Pulses Processing Plant

Pulses Processing Plant

Pulses Processing Plant

Pulses Processing Plant

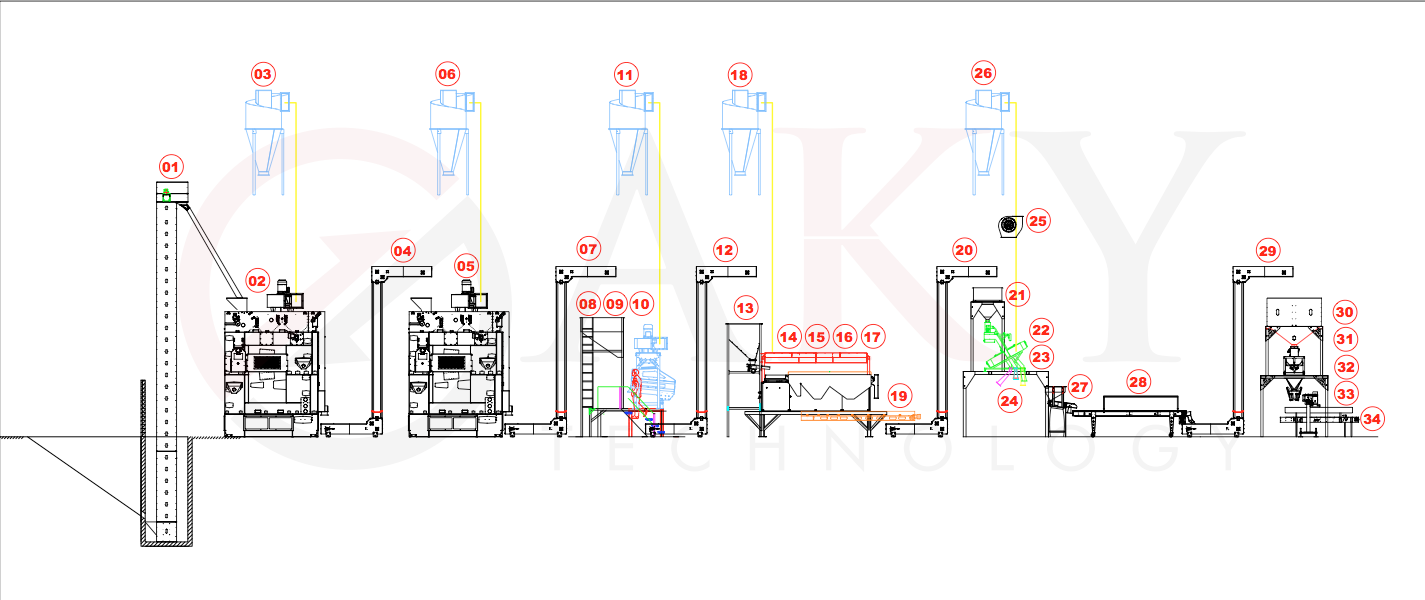

In Pulses processing plant, unprocessed products passes from screening machines for screening raw and broken products and for calibrating process. Later, products could be bagged as per request in bagging machine

The aim of this plant is; getting maximum value of pure products with high quality technological machines.

In Pulses Processing Plant;

1) Sensitive Cleaning Machine; screens the dust, corp, chaff, etc. from the product and finishes the pre-celaning process. Later; for sorting the high density things, product enters to the stone separator.

2) Stone Separator is mostly for sorting impurities like; stone, glass, dust, etc. Later the product enters to the Gravity Separator for separating light products.

3) Gravity Machine is used for separating the light materials from the product. This machine finalize the cleaning process. On the next step; product passes to the color sorting machine.

4) Color sorting machine is mostly used to separate and calibrate the processed product to their color and type. Thus; the products purity level increases to %99,8.

5) Scale and Bagging Machine is used to weighing and bagging the processed products with optional