Function :

Many food grain and seed crops need to separated by color which can effectively be done in an electronic sorter utilizing optical lens or CCD Camera and compressed air jets to identify and discard and particles that do not fit the color profile programmed into the machine. These operate automatically and are extremely reliable.

AKY Color Sort optical color sorting machine separates the discolored kernel from good kernels which have already pre-cleaned. Quality of screened product increases to %99,8. AKY Fotosorter Color sorter machine constructed with latest technology available to the industry.

Work Principle :

An elevator feeds kernels into hopper which is located on top of the color sorter. From hopper kernels fed in to machine from 3 channels out of four. Kernels flow downwards as a thin layer passing by in front of CCD cameras. These cameras detect the discolored kernels, kernels that are low quality. CCD cameras send commands to computer program and program converts the commands for ejectors to separate these kernels from the good kernels. These low quality kernels fed back in to the system from the last channel and discolored kernels re-sorted by color sorter. This way, product wastage reduces.

CCD cameras can detect discoloration on a kernel as small as 0,008 mm2. Machine is programmable for product quality variations. Integrated computer program alerts of faults and errors that machines can come across whilst operating.

Capacity :

Please note that the accept and reject quantities that can be obtained are interdependent and also depend on the input contamination. The throughput capacities shown are also dependent on the input contamination and the required quality of accept and reject.

Capacities can range considerably between commodities and for most applications we suggest a color sort test to determine the results that may be obtained and the capacity rate per channel.

In lines with capacity enlargement, for operations that are multi commodity color sorting AKY Technology can manufacture color sorter with more than one re-sort channel.

| Makine Çeşitleri/

Machine Type |

B2 |

B3 |

B4 |

B5 |

B6 |

B7 |

| Voltaj / Voltage |

AC220V 50HZ |

AC220V 50HZ |

AC220V 50HZ |

AC220V 50HZ |

AC220V 50HZ |

AC220V 50HZ |

| Güç / Power (KW) |

1,0 - 2,7 |

1,0 - 2,7 |

1,2 - 7 |

2-4,5 |

4,5-6 |

2-4.5 |

| Gereken Hava Oranı

Air Consumption(L/min) |

1000 |

1000-1800 |

1200-2500 |

1800-4000 |

4000-6000 |

<4500 |

| Ağırlık/Weight (kg) |

750 |

850 |

950 |

1050 |

1250 |

1200 |

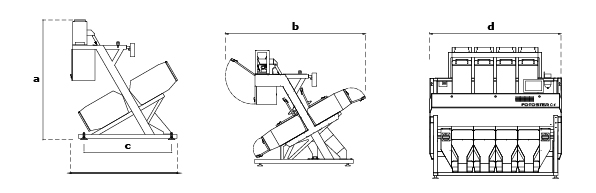

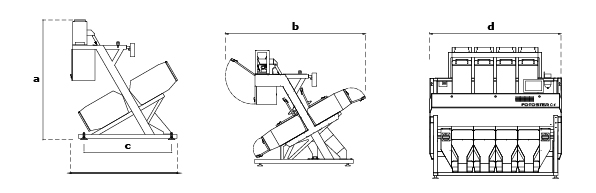

| a

Ölçüler / Dimensions (mm) |

1.880 |

1.880 |

1.950 |

1.950 |

1.950 |

1.953 |

| b

Ölçüler / Dimensions (mm) |

1.642 |

1.642 |

1.642 |

1.642 |

1.642 |

2.200 |

| c

Ölçüler / Dimensions (mm) |

1.580 |

1.580 |

1.580 |

1.580 |

1.580 |

1.607 |

| d

Ölçüler / Dimensions (mm) |

1.310 |

1.620 |

1.950 |

2.310 |

2.660 |

2934 |

| Kamera Sayısı (Adet)

Number of Cameras (Piece) |

4 |

6 |

8 |

10 |

12 |

14 |

| Ejektör Sayısı (Adet)

The number of ejektor (Piece) |

128 |

192 |

256 |

320 |

384 |

448 |

| Kamera Tipi

Camera Type |

Trikromatik CCD Mono |

Trikromatik CCD Mono |

Trikromatik CCD Mono |

Trikromatik CCD Mono |

Trikromatik CCD Mono |

Trikromatik CCD Mono |

| Trikromatik CCD Color |

Trikromatik CCD Color |

Trikromatik CCD Color |

Trikromatik CCD Color |

Trikromatik CCD Color |

Trikromatik CCD Color |

| IR Camera

Infread Camera |

Opsiyonel

Optional |

Opsiyonel

Optional |

Opsiyonel

Optional |

Opsiyonel

Optional |

Opsiyonel

Optional |

Opsiyonel

Optional |

| Kanal Genişliği (mm.)

Channel Width (mm.) |

330x2 |

330x3 |

330x4 |

330x5 |

330x6 |

330x7 |

| Çıkış Oluğu Sayısı

The Number of Output Ducts |

5 |

7 |

9 |

11 |

13 |

15 |

| Ses Düzeyi

Noise Level |

80 dB |

80 dB |

80 dB |

80 dB |

80 dB |

80dB |

| Kapasite

Ton/Saat

Capacity

Tonnes / Hour |

Buğday

Wheat |

Min 0.6

Max 3 |

Min 0.9

Max 4.5 |

Min 1.2

Max 6 |

Min 1.5

Max 7.5 |

Min 1.8

Max 9 |

Min 3.5

Max 14 |

| Kapasiteler NSA ürün içerisindeki kirlilik miktarına göre değişiklik gösterebilir.

Capacities very based on the amount of pollution in the NSA product. |